Valley Rubber is positioned to serve our customers with a unique set of capabilities ranging from rubber molding and fabrication to engineering.

Valley Rubber is positioned to serve our customers with a unique set of capabilities ranging from rubber molding and fabrication to engineering.

Molding Capabilities

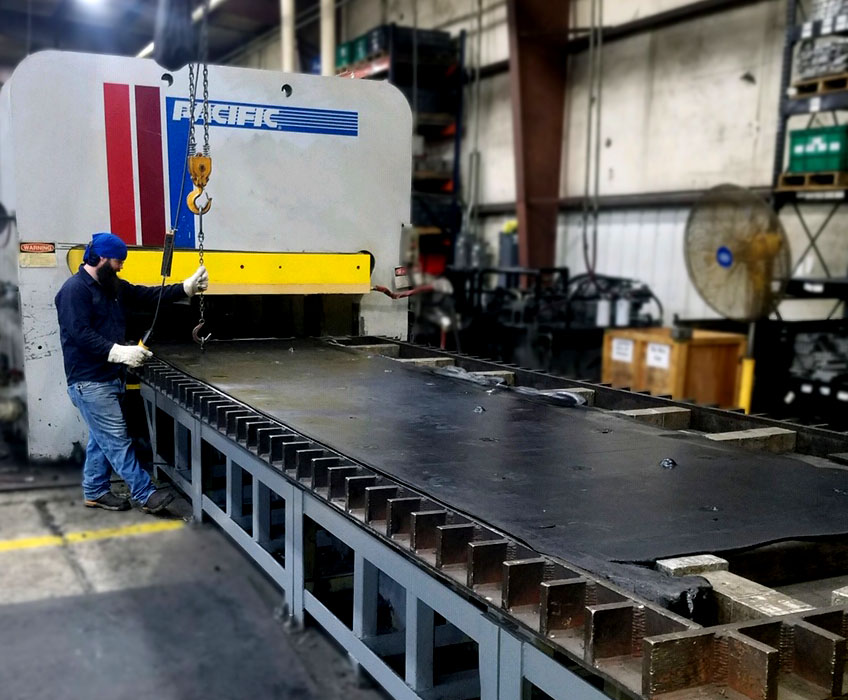

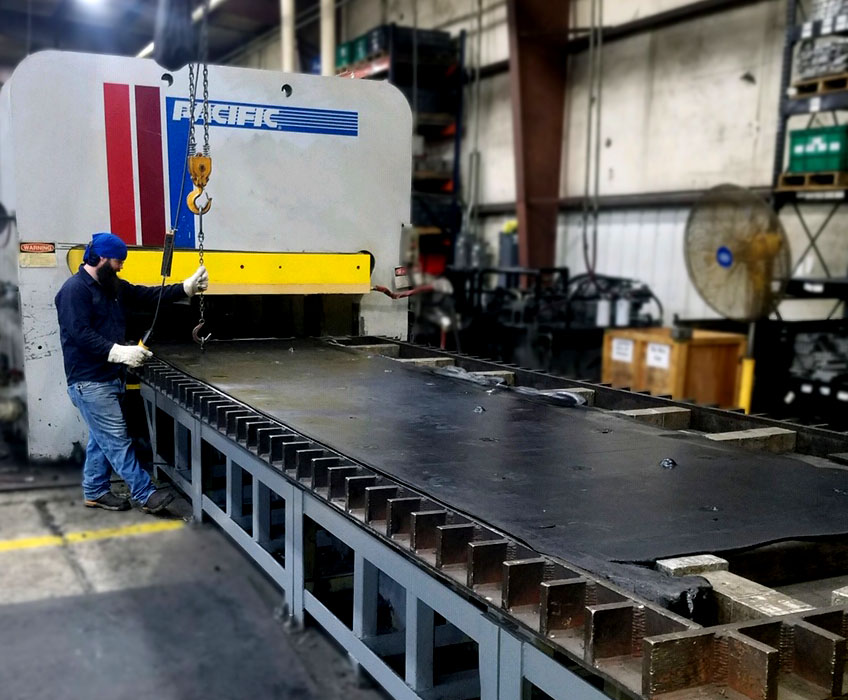

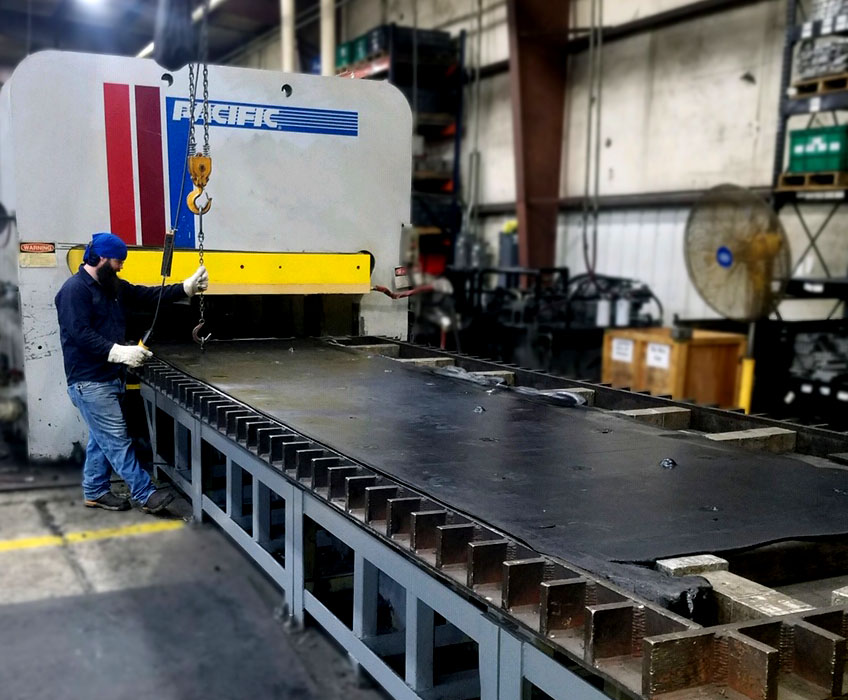

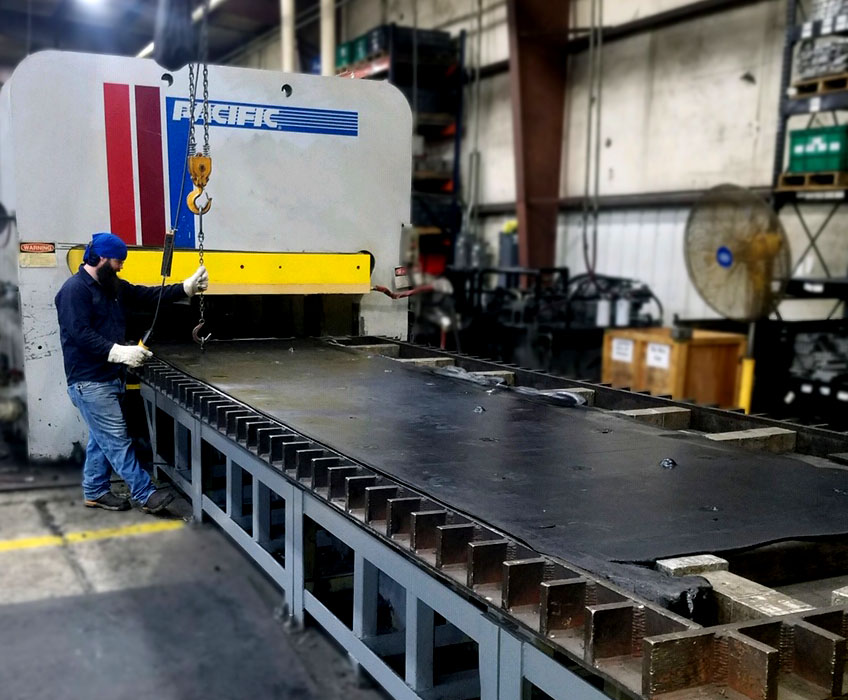

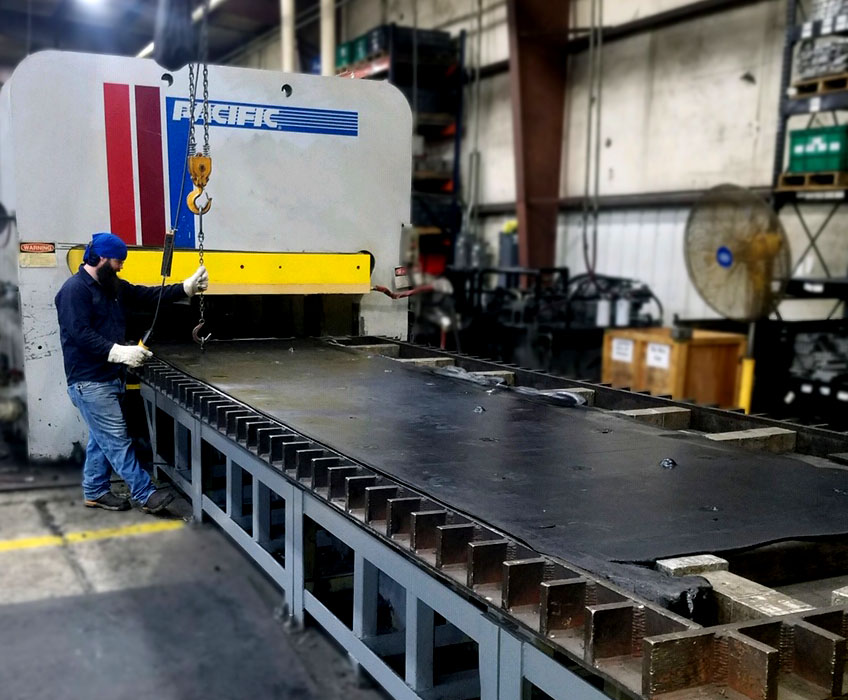

• Large Compression Molding- With more than forty presses, we can meet volume requirements while offering unique capabilities for big parts. Press sizes range from a small 12-inch square platen to very large presses with a platen as large as 7 feet by 20 feet. Valley Rubber has a concentration on large molded parts.

• Rubber to Substrate Bonding- Valley Rubber has extensive experience in bonding a wide variety of materials to rubber. Our bonding solutions have been put through very rigorous field and lab testing with outstanding results. We bond rubber to steel, aluminum, ceramic, UHMW-PE, fabric, magnets and more.

• Creative Solutions- We are equipped to provide custom solutions for most applications. Often it is cost prohibitive to build a machined mold for just a few parts. We take a creative approach to manufacturing that will reduce or eliminate the need for expensive molds in many situations. It is common for Valley Rubber to make 1 or 2 parts to fill a customer’s need.

Fabrication Capabilities

• Internal fabrication

• Quicker lead times

• Direct access to our engineers

• Project management

• Provide steel cutting, welding, fabrication, forming, protective painting, & more

Engineering Capabilities

Contact us today to see how we can help solve your toughest operational issues!